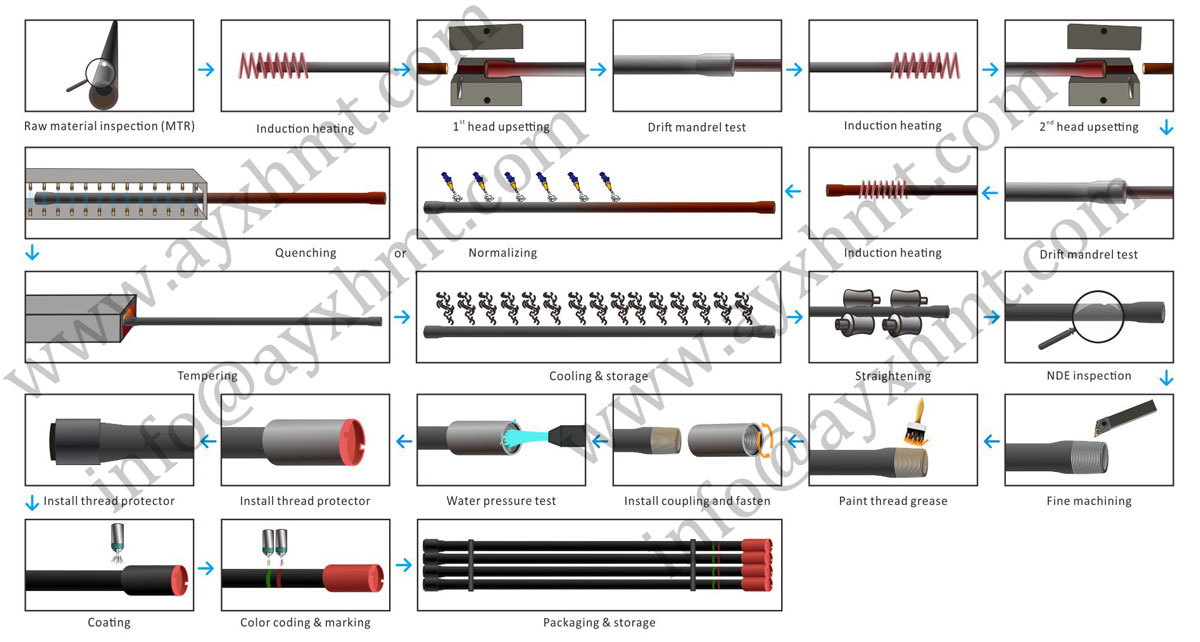

API 5CT external-upset tubing production line is composed by induction heating furnace, automatic feeding and discharging device, hydraulic upsetting press, drift mandrel testing machine, tubing heat treatment line, hydraulic straightening machine, oil country lathe, hydrostatic testing machine, pipe coupling fitting machine, coating machine, color coding machine, etc.

I. Product range

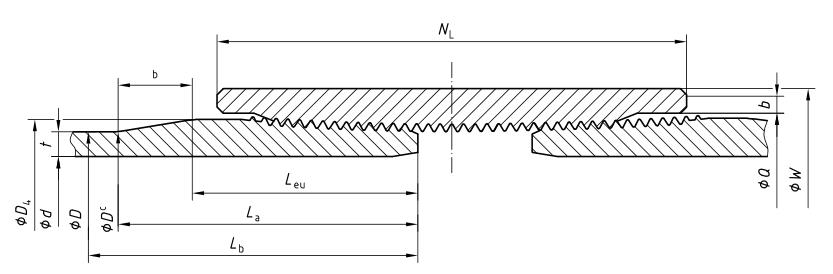

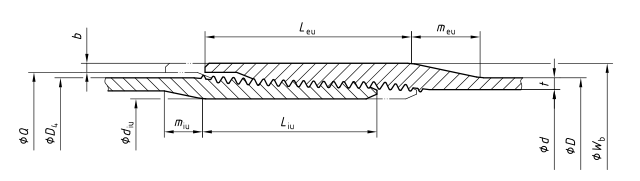

1. Drawing of external-upset tubing and integral-joint tubing

External-upset tubing

Integral-joint tubing

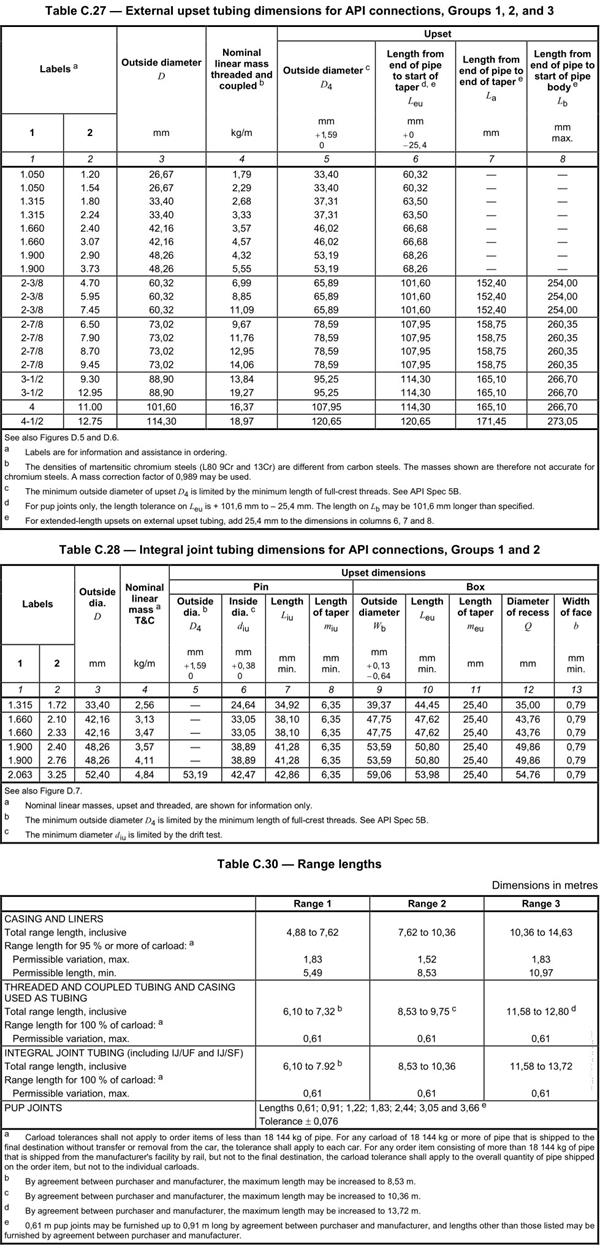

2. Dimension of external-upset tubing and integral-joint tubing

3. Material of tubing

H40, J55, L80, N80, C90, T95 and P110.

II. Productivity

1 piece/min, 2 shifts/day, 260 working days/year.

Productivity per year 1×60×2×8×260=249,600 pcs

III. Key equipment description

1. Hydraulic upsetting press

Hydraulic upsetting press chosen for this production has enough capacity to upset the minimum and maximum tubings from  ” to

” to  ” (from 60.3 mm to 114.3 mm ).

” (from 60.3 mm to 114.3 mm ).

2 sets of hydraulic upsetting presses are placed simultaneously, one set of hydraulic upsetting press is used to finish upsetting to one end of tubing, another set of hydraulic upsetting press used upset another end of tubing, which greatly increase the productivity and efficiency.

The whole upsetting processes, from including tube loading, tube conveying, feeding, induction heating, die clamping, upsetting, die cooling and die lubrication, are full automatic.

2. Drift mandrel testing machine

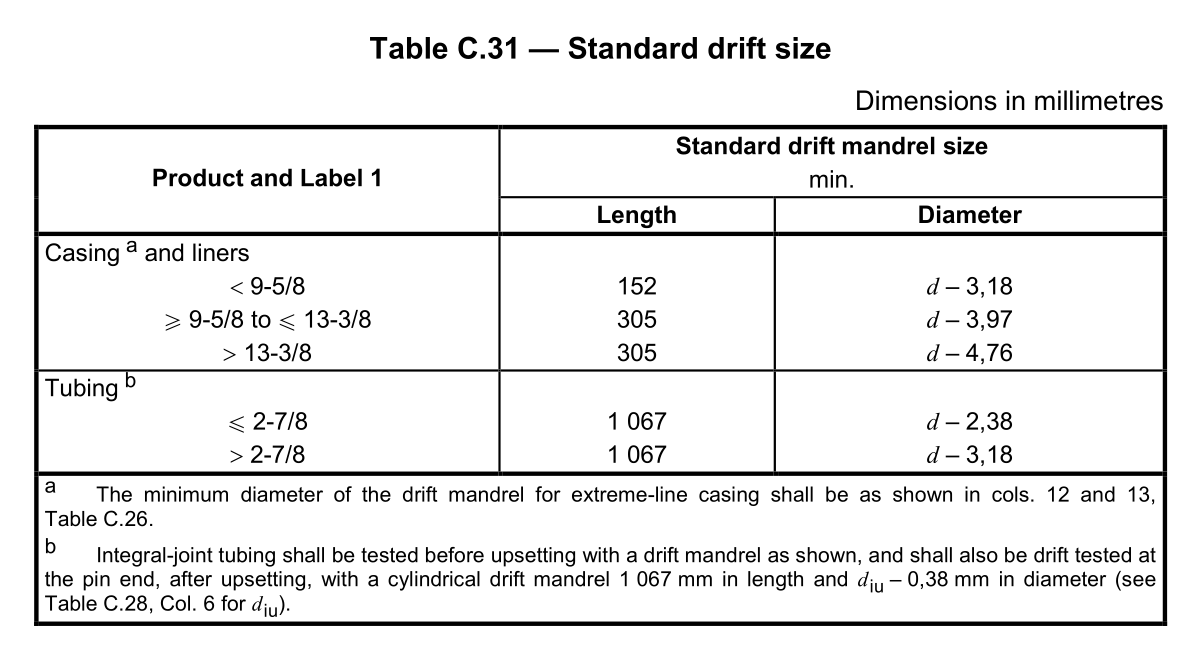

After upsetting, drift mandrel testing should be done according to API 5CT standard.

This drift mandrel testing machine is a special equipment for oil pipe diameter quality inspection. It adopts standard diameter gauge to test the cylindricity and straightness of the oil pipe. The oil tubing drifting mandrel testing machine meets the requirement of Table C.31- Standard drift size in API SPEC 5CT standard.

3. Oil country lathe

Our company can supply economy type flat bed CNC oil country lathe, moderate slant bed CNC oil country lathe and high performance CNC oil country lathe.

Economy type flat bed CNC oil country lathe is equipped with double pneumatic chucks, V4 electric turret, SINUMERIK808D or Fanuc 0i-TF CNC system.

Moderate slant bed CNC oil country lathe is equipped with double hydraulic chucks, H8 hydraulic turret, Fanuc 0i-TF CNC system.

High performance CNC oil country lathe is equipped with DC spindle motor with big toque, double hydraulic chucks, upper turret is H8 turret, lower turret is high positioning precision turret only for threading. The productivity is 4-5 times of ordinary oil country lathe.

All of 3 types of oil country lathe can meet the precision requirement of API 5B standard.

4. Hydrostatic testing machine

The tubing hydrostatic testing machine adopts advanced radial sealing method, which requires end face sealing without thread connection, and adopts a wedge bearing device.

The human-machine interface and the computer real-time monitoring system can display the pressure curve and value in real time, and cumulatively record and save each parameter.

When working, set various parameters (such as pipe number, pipe diameter, wall thickness, steel grade, pressure, holding time, date, operator number, etc.) according to the API standard, and the tubing automatically enters the equipment through the storage rack. Then the hydrostatic testing is started automatically. After reaching the set pressure and pressure holding time, the load will be automatically unloaded and the tubing will be sent to the storage rack. If tubing is qualified, the next tubing is sent to testing machine; if it fails, an audible and visual alarm will be given.

Message

If you have any suggestions or question for us.Please contact us.