AE series slant bed CNC lathe

1. High rigidity casting

Lathe bed, headstock, saddle and tailstock are all made of high rigidity castings. In order to ensure durable precision, those components of lathe will be processed with tempering treatment and long time natural aging treatment.

2. High precision and high rigidity spindle

The spindle is equipped with NSK P4 grade ultra-precision NN type bearings with optimized span (4 bearings in the front and 2 bearings in the back), precision and rigidity are warranted under the condition of high speed rotation and heavy cutting.

3. Precision and heavy duty linear guide and screw

High precision, heavy duty linear guides from Rexroth, HIWIN and PMI with automatic centering function are used. Pre-tightened C3 grade high precision ball screw and long double nuts are applied in our lathe with outstanding precision.

4. Superior quality tailstock

The tailstock quill is controlled by less than 5kg hydraulic pressure, which can effectively prevent deformation of the long shaft workpiece and lathe bed.

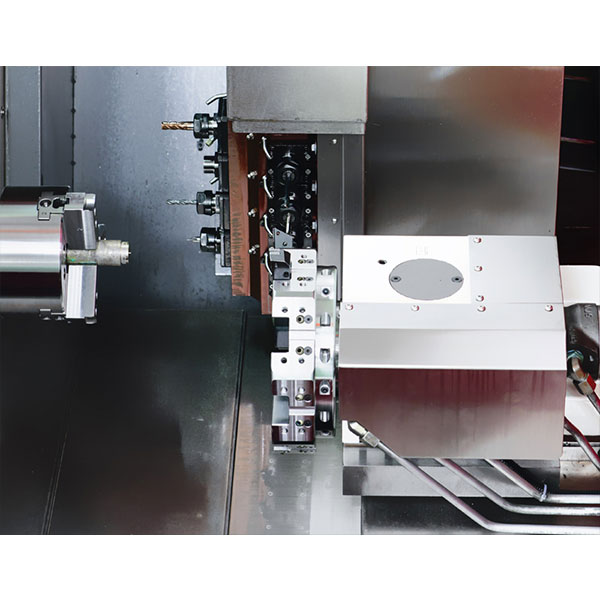

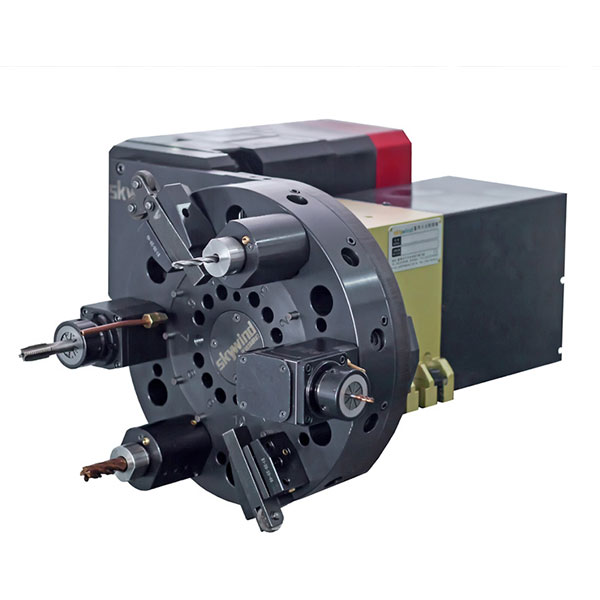

5. Multifunctional hydraulic turret and servo turret

Our lathe can be equipped with hydraulic turret and servo turret, drilling power head and milling power head can be installed to realize turning, boring, drilling, tapping and milling processes on one lathe. 4 power heads on the side of turret, another 4 power heads on the end of turret can be installed at the same time, totally 8 power heads with high rotation speed and large torque can be linkaged.

6. Optional C-axis

Message

If you have any suggestions or question for us.Please contact us.